This past September, the Metro Nashville District Energy System (MNDES) executed a planned service outage to complete significant maintenance projects related to steam energy production and delivery involving five separate locations across the energy distribution system (EDS) plus the Energy Generating Facility (EGF). The project anticipated a 24-hour shut down period but required less than 17 hours before steam service was restored to all customers. MNDES provides steam energy service to 37 buildings operated by 21 customers.

“We were very pleased with the great teamwork and committed performance of all parties involved in this project, especially the coordination from long-time team members Eddie Wisdom and Chuck Tucker. Like many of the Constellation staff, Chuck and Eddie have worked at the current facility since it was opened in 2003. Nashville’s great district energy system has a very diversified customer base, all with their own unique service requirements,” stated Mike Winters, General Manager of MNDES, and employee of Constellation, the operator of the system for the city, “Minimizing down time is always a driving factor in our ongoing efforts to serve their needs.”

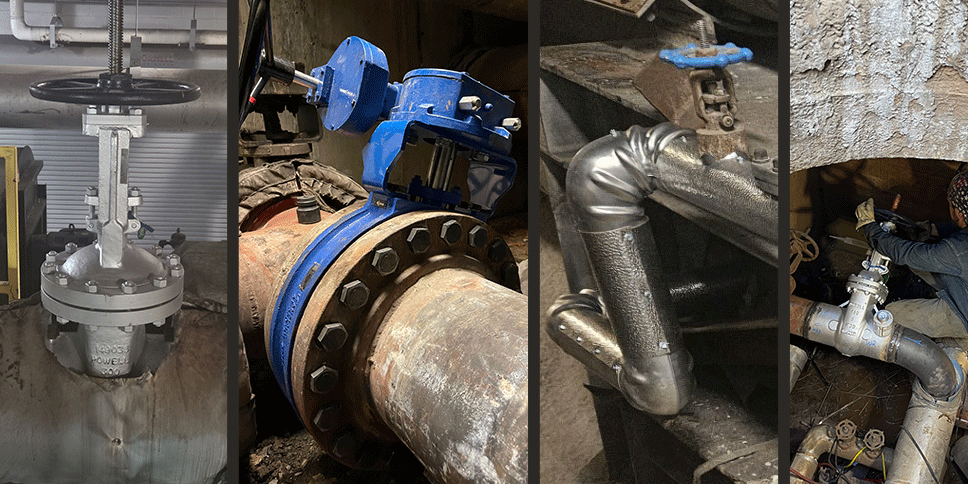

The service outage involved shutting down steam production boilers at the EGF and depressurizing the entire steam portion of the EDS so that various components across the system could be replaced or repaired. The project began at 11:00 PM on September 24th, and all customers were back online by 3:30 PM on September 25th. Bringing steam customers back online involved direct contact with each of them. Some customer staff members coordinated with Constellation personnel while others relied on Constellation employees to re-energize their buildings as the system came back online.

“We put the Nashville District Energy customers’ needs first in planning this type of system service,” added Winters, “Coordinating and communicating with customers regarding their scheduled activities and energy requirements is paramount. We make certain they know exactly what to expect and when to expect it. Then we follow through to ensure that any project like this has the least possible disruptive impact to their ongoing operations.”

Developing a plan for a project of this magnitude involves the work and coordination of multiple parties. As part of ongoing system component inspections, Thermal Engineering Group, the NDES project administrator, identifies and lists service projects that can be postponed for a period of time then grouped together to be addressed when a single system shut down can be scheduled. “This project was a good example of a single urgent priority project being paired with other identified issues so that we could complete multiple requirements in a single window,” stated Dan Coyle, President of Thermal Engineering Group, “some of the work included in this project required immediate attention prior to entering the primary heating season this winter. Other items had been identified and prioritized earlier so that they could be added to the scope in a situation like this to minimize system disruption.”

Work on this project was completed at six separate locations, five within the vaults and tunnels of the EDS and one at the EGF. The project involved extensive lead time planning, ordering and delivery of specialty parts, scheduling and management of specialized skilled contractors, and street closure permits for manhole access and traffic coordination. Coordination in advance with all customers ensured that the service event timing occurred when it would have the least possible impact to the customers’ operations.

The MNDES system provides both steam and chilled water services to the downtown district of Nashville. MNDES chilled water service continued to operate normally and without interruption during this event. For the past nineteen years, MNDES has operated at a 99.84% reliability for steam energy and a 99.95% reliability for chilled water. Careful planning and performance, as demonstrated in this service project, have been significant contributing factors to the ongoing outstanding reliability of the MNDES.

For more information, contact Dan Coyle, Thermal Engineering Group and NDES project coordinator at 615-261-2611