The Metro Nashville District Energy System (DES) has provided heating and cooling to buildings in downtown Nashville for over four decades. In 2001, it was decided to replace the aging Waste-to-Energy Nashville Thermal Transfer Corporation (NTTC) facility (“Thermal”) with a new District Energy System in downtown Nashville. The new DES was implemented with several important objectives in mind:

- To utilize state-of-the-art equipment with high reliability;

- To keep costs as reasonable as possible and very predictable to the customers;

- To be a visually attractive facility and environmentally friendly;

- To be a long-lasting project that contributes positively to the economic stability and growth in downtown Nashville.

In November 2002, construction began on the new state-of-the-art facility and operation began December 16, 2003. By January 2004 the plant was fully operational. The new DES facility provides steam and chilled water to heat and cool 42 downtown buildings.

What is District Energy System?

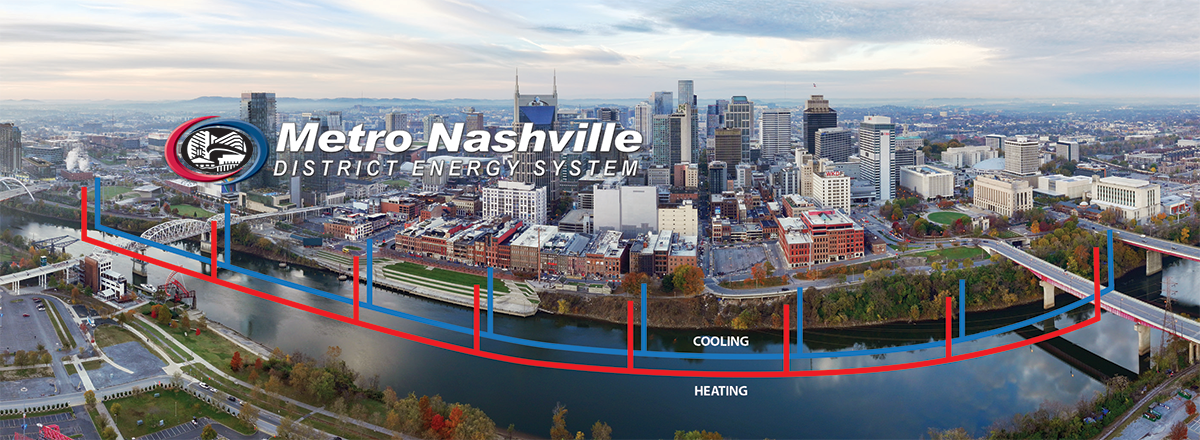

A district energy system provides heating and cooling services to multiple users, essentially taking the place of each building’s self-contained HVAC unit. District energy plants are usually located in large urban areas and supply downtown customers.

How Does District Energy System Work?

At the Metro Nashville DES facility, natural gas and electricity are used to produce steam and chilled water. The steam and chilled water is then distributed through a series of underground pipes to 42 individual buildings in the downtown area. These buildings don’t require boilers, furnaces, chillers or use fuel or electricity in water heaters; the DES does that work for them.

History of Metro Nashville District Energy System

Shortly after taking office, Mayor Bill Purcell commissioned a study that evaluated Metro’s solid waste management system. This study included an independent evaluation of Nashville Thermal Transfer Corporation (NTTC), which found the cost of disposal at NTTC high and the plant’s operations unreliable. Based on the results of the study, the Mayor recommended, and the Council approved, the “Clean, Green, Lean” Waste Management Plan, which provides for greater waste diversion programs for the city and a new district energy system (DES).

As part of the new plan, Metro decided to phase out NTTC as a waste disposal option, enter into long-term contracts for the disposal of waste, and change the district energy plant to a natural gas-fired system. NTTC agreed to shut down the waste-burning components of the waste-to-energy facility by September 30, 2002, and to switch to natural gas-fired boilers to generate steam and chilled water. However, a fire in the waste receiving area occurred in May 2002, causing early closure of the waste-fueled system.

The Thermal plant operated as a natural gas-fired facility using four boilers to produce steam and chilled water until January 2004, when the new energy generation facility (EGF) became fully operational. The NTTC plant was then torn down to make way for urban development on the riverfront property where it currently sits.

NTTC Timeline

1970 – Nashville Mayor Beverly Briley began studying the feasibility of building a plant that would address the city’s solid waste disposal needs and recapture energy to heat and cool buildings in the downtown area.

1973 – The Nashville Thermal Transfer Corporation (NTTC), a not-for-profit organization, was established to build, own, and operate the $16.5 million district energy system. Construction was financed by energy bonds.

1974 – The plant began operations in February, making Nashville the first city in the world to use solid waste as an energy source for both heating and cooling. The plant was capable of burning 1,000 tons of trash per day. The energy created by this waste-burning process was used to generate steam, which was then used to heat downtown buildings, or to produce chilled water to cool the buildings.

1976 – Electrostatic precipitators were installed to reduce air emissions at a cost of $8 million.

1984-1986 – The facility underwent a $36 million expansion, giving it the ability to generate electricity and expanding its capability to serve downtown heating and cooling customers.

1999 – The air pollution system was replaced with a combination baghouse-scrubber system to abide by new, stricter amendments to the Clean Air Act.

2001 – Despite several expansions and updates to improve operations and to increase its capacity during its 30-year life span, the NTTC struggled to meet pollution restrictions and to remain economically viable. Because of this, Metro Council voted in December to close the NTTC plant by 2004, and Mayor Bill Purcell announced plans to modify the DES from a solid waste-fired system to a fossil fuel system by 2004.

2002 – As part of the scheduled closing, the plant was to start fueling the facility with natural gas instead of trash by October 2002. This process was accelerated by a major fire on May 23, 2002, which immediately halted the burning of trash. The plant was back in operation only one business day after the fire, and continued to operate as a gas-fired facility, producing steam and chilled water as before.

Mid-December 2003 – The new DES facility came online mid-December 2003 and was fully operational serving downtown customers in January 2004. The old NTTC facility was demolished to make way for riverfront development on the property which it occupied for nearly three decades.

Benefits of District Energy System

Economic

- Reduces upfront capital costs because the equipment necessary to tie into the DES system costs less than stand-alone systems

- Lower overall building operating, maintenance, and labor costs

- Passes along economies of scale when purchasing fuel

Environmental

- A central plant serving multiple customers is more efficient than individual small plants, thereby reducing overall energy consumption

- Virtually 100% of the steam and chilled water energy delivered to the customer is available for use within his facility whereas smaller in-building boilers and air-cooled chiller systems can require up to 50% more energy to deliver the same heating or cooling benefit

- Central plants employ stringent emission controls – more so than individual buildings – providing air quality benefits

- Chilled water services from a central plant reduces peak electric power demand for air conditioning

Convenient

- Removes combustion and refrigerant equipment from buildings, saving space in the buildings for other uses and removing a real source of possible indoor air quality contamination

- Eliminates need for boilers and chillers resulting in less maintenance, monitoring and equipment permitting

- Energy professionals at central plants operate around the clock and have backup systems available, with reliability rates near 99.9 percent

- Building operators can manage and control their own indoor environments because district energy is available whenever heating or cooling is needed (i.e. – the air conditioning can be turned on for an unseasonably warm January day)

Metro Nashville DES Facts

- Construction began on the $48.3 million Metro Nashville District Energy System (DES) facility in November 2002; work was completed and the new DES facility began operating in December 2003, seven months ahead of schedule.

- The DES facility provides steam and chilled water to heat and cool 42 downtown buildings.

- There is approximately 97,433 feet of piping in the DES system. Of the 97,433 ft, approximately one-fourth is chilled water supply, one-fourth is chilled water return, one-fourth is steam (supply) and one-fourth is condensate (return.) These four pipes are run parallel through most of the system in approximately one and a half miles of tunnels and two and one half miles of direct buried trenches. Some chilled water piping also hangs from the Woodland Street bridge.

- DES is one of Nashville Electric Service’s largest customers.

- The largest DES customer is Metro, which has 11 buildings on the system, including the new Convention Center.

- The facility operates nine chillers and four boilers, and has the capacity to provide 23,400 tons of chilled water for cooling and 260,000 pounds of steam for heating.

- DES circulates chilled water at a rate of up to 42,000 gallons per minute.

- Steam travels through the pipes to downtown buildings at an average rate of 70 miles per hour.

- Nearly 100 percent of the chilled water supplied to customers for cooling is returned and recycled, while 70 percent of the water used for steam is returned and recycled.