The Nashville District Energy System Annual Customer Meeting held May 29, 2025, included a presentation of the system’s overall performance for several years across a number of key performance indicators. Thermal Engineering Group which serves as the MNDES Project Administrator for Metro government is responsible for many administrative and technical tasks, including the Annual Customer Meeting. Among the various discussion points presented, Kevin L Jacobs, P.E. (the presenter from TEG) provided specific detail to encourage customers to carefully inspect and repair piping insulation in their facilities with an emphasis on the steam and condensate systems. Below is a detailed narrative of that section of the presentation.

Mr. Jacobs shared information with customers relating to how damaged or missing pipe insulation poses several issues for building operators and personnel. Lack of adequate insulation on steam and condensate piping creates hazards in locations where people can come in contact with the piping. The surface temperature of the piping may exceed the OSHA limitation 140°F. Too little insulation on chilled water piping can cause condensation to form on the outside of the piping, valves, and fittings which can drip onto equipment or other surfaces, damage any insulation remaining on the chilled water piping and adjacent piping, create environments suitable for mold and mildew growth, and lead to long-term corrosion issues.

Besides personnel protection and condensation control, piping insulation reduces the amount of heat transfer to the spaces within the building. The heat lost from steam piping often leads to a higher steam usage which may not provide any space or domestic hot water heating. The lost heat from both the steam and condensate piping into conditioned spaces may also increase the amount of cooling required for those spaces, resulting in even higher chilled water usage. Without proper insulation, building owners may find themselves in a perpetual loop of wasting steam heat and having to pay for the chilled water to cool the room air to appropriate temperatures.

Repairing, replacing, or installing missing or damaged insulation is an easy solution to increase building energy savings. A competent insulation contractor experienced with steam and chilled water piping may be able to fix your insulation issues within a day or so. We recommend contacting several piping contractors and getting some firm quotes if you need assistance in repairing or replacing insulation.

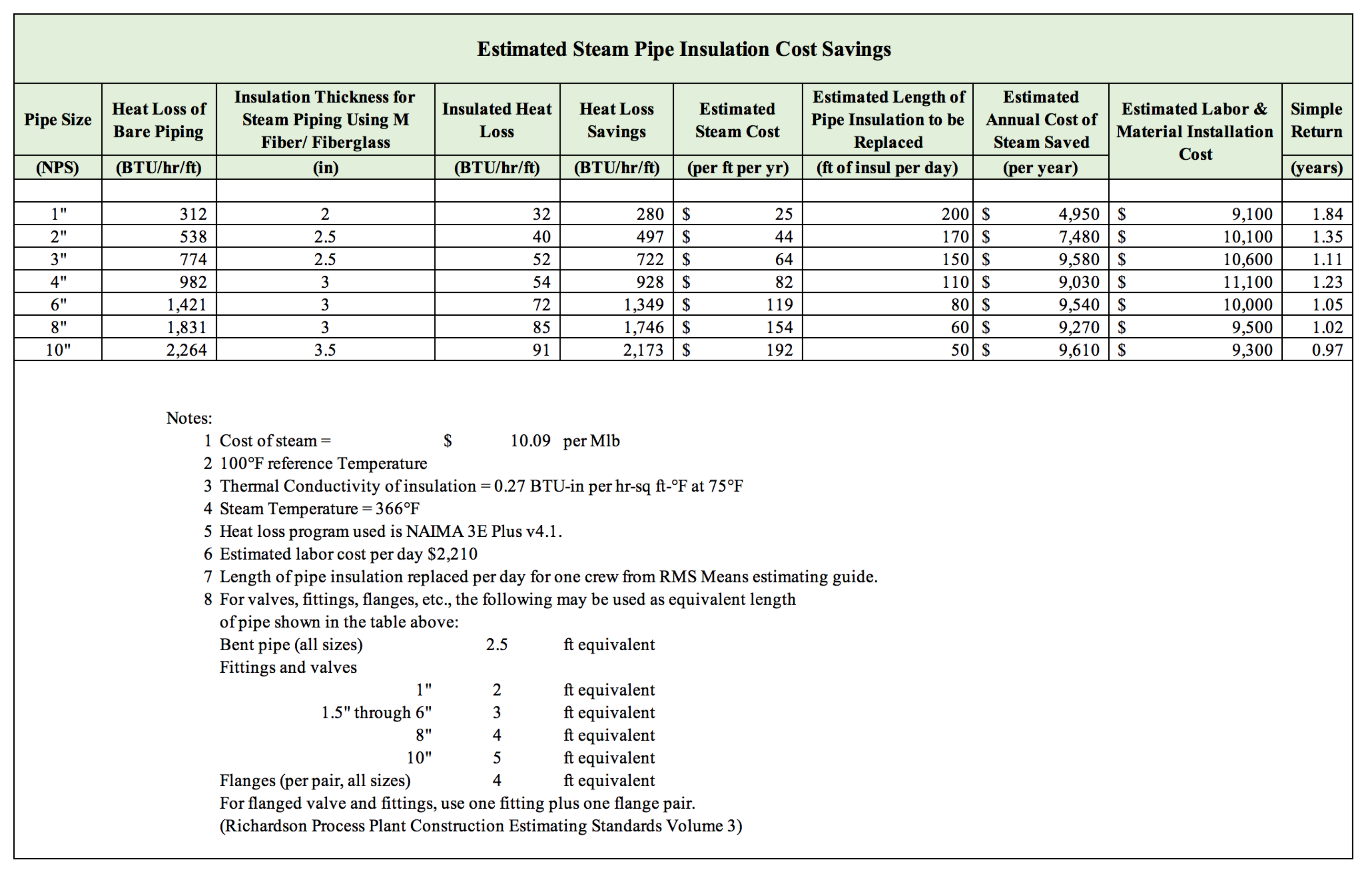

The following table provides a summary of how much the insulation may cost on steam pipe and how much money could be saved.

This table lists the heat loss for bare steam pipe for various pipe sizes. If an appropriate thickness of appropriate insulation is installed, the heat loss will be dramatically reduced. In addition, the surface temperature of the insulation will drop well below the OSHA limit of 140°F. At $10.09 per Mlb of steam from DES, the estimated steam cost may seem low ($25 per foot per year for 1” pipe), but you will most likely never just insulate 1 foot of pipe.

The smaller the pipe size is, the more feet of insulation can be installed in a day. The material costs estimated in the table are based on the estimated length of pipe insulation which can be replaced in a one day based on the RMS Means Estimating Guide. By installing the length of insulation shown, you may save between $5,000 and $10,000 per year in steam costs from DES! The estimated cost for one day’s worth of insulation installation may cost around $10,000 but could result in a simple return of around one year!

MNDES recommends keeping steam, condensate, and chilled water piping in top condition to save money and help prevent other unpleasant issues from occurring. Sealing the ends and seams of the insulation is crucial, too. If you have piping in locations where the insulation is easily damaged, you may want to install aluminum or stainless steel lagging to provide a little extra protection!